Twice, SAM4 Health provided early warning of gearbox degradation though the vibration system had not yet alerted the customer to a problem.

Problem

Aeration rotors are essential assets in the wastewater treatment process. A broken rotor instantly reduces site capacity — but the incoming flow doesn’t slow down. To avoid the risk of a pollution incident, it’s critical to know when oxidation ditch rotors are degrading, so preventive maintenance can be planned at a time that does not endanger the plant’s ability to keep up.

Solution

At a wastewater treatment plant, SAM4 Health is installed on four aeration rotors. During the first year of monitoring, SAM4 alerted the customer to two developing faults on one of the rotors. Thanks to these alerts, the customer was able to schedule and perform the required maintenance without disruption to site capacity.

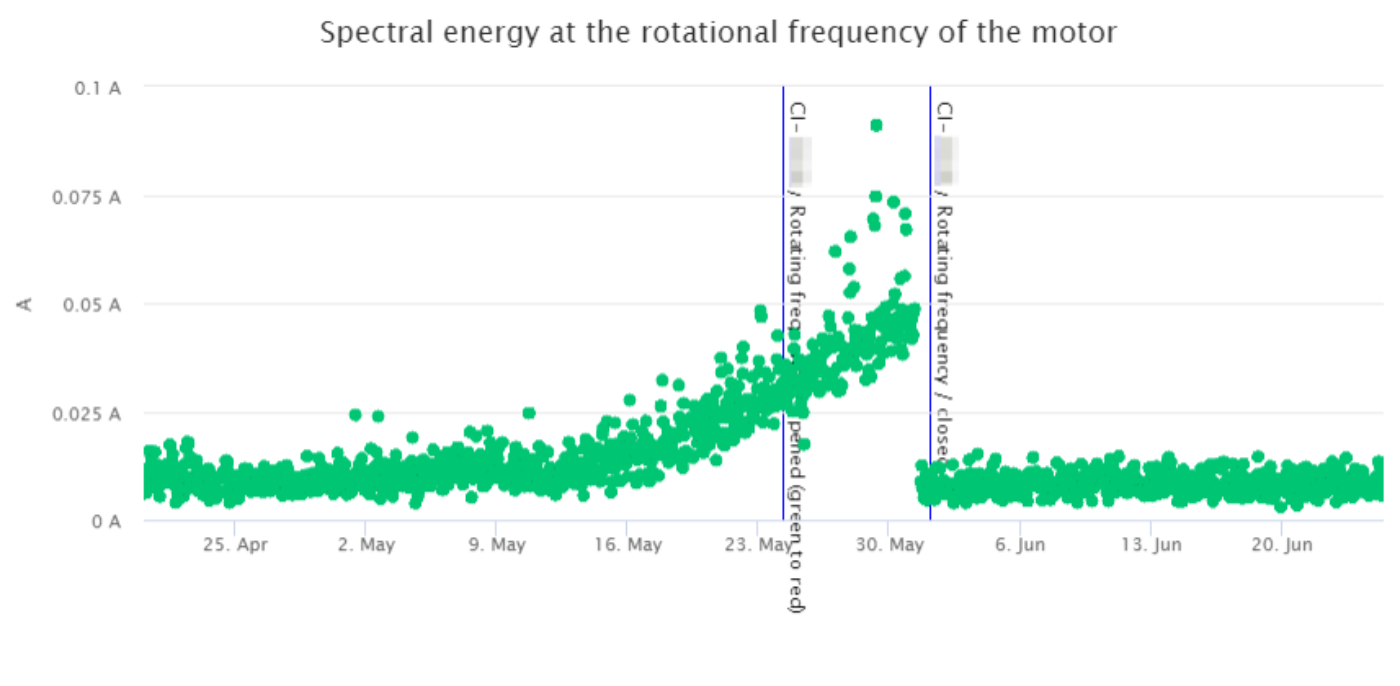

In both cases, SAM4 detected an increase in spectral energy at the rotational frequency of the motor, which is an indicator for mechanical unbalance. The customer also has a vibration condition monitoring system installed on the rotor, but that system had not yet alerted to an anomaly in either case. In both cases, the customer replaced the gearbox. After this maintenance, SAM4 confirmed a return to healthy behavior.

Result

Thanks to SAM4’s early alerts, the customer was able to avoid two critical disruptions to its wastewater treatment process. These two detections prevented €54k in maintenance costs, €40k in emergency mitigation costs, and up to €800k in pollution event fines.