About Sabesp, one of Brazil’s largest utilities

Founded in 1973, Sabesp (Companhia de Saneamento Básico do Estado de São Paulo) is one of the largest sanitation companies in the world. It provides water and wastewater services to more than 28 million people across 370 municipalities in the state of São Paulo. The company must ensure reliable performance of its network while also dealing with high energy costs.

Continuous monitoring to unlock performance

Sabesp operates thousands of submersible pumps, but conventional monitoring methods offered them little visibility into how efficiently these submerged assets were running. Without real-time insights, inefficiencies or blockages could also go unnoticed, reducing reliability and increasing energy use and operational risk.

To tackle this challenge, Sabesp implemented SAM4, Samotics’ smart asset monitoring system. Because its sensors are installed in the motor control cabinet rather than on pumps themselves, SAM4 is uniquely suited for monitoring submerged and otherwise hard-to-reach equipment.

Insights that drive tangible savings

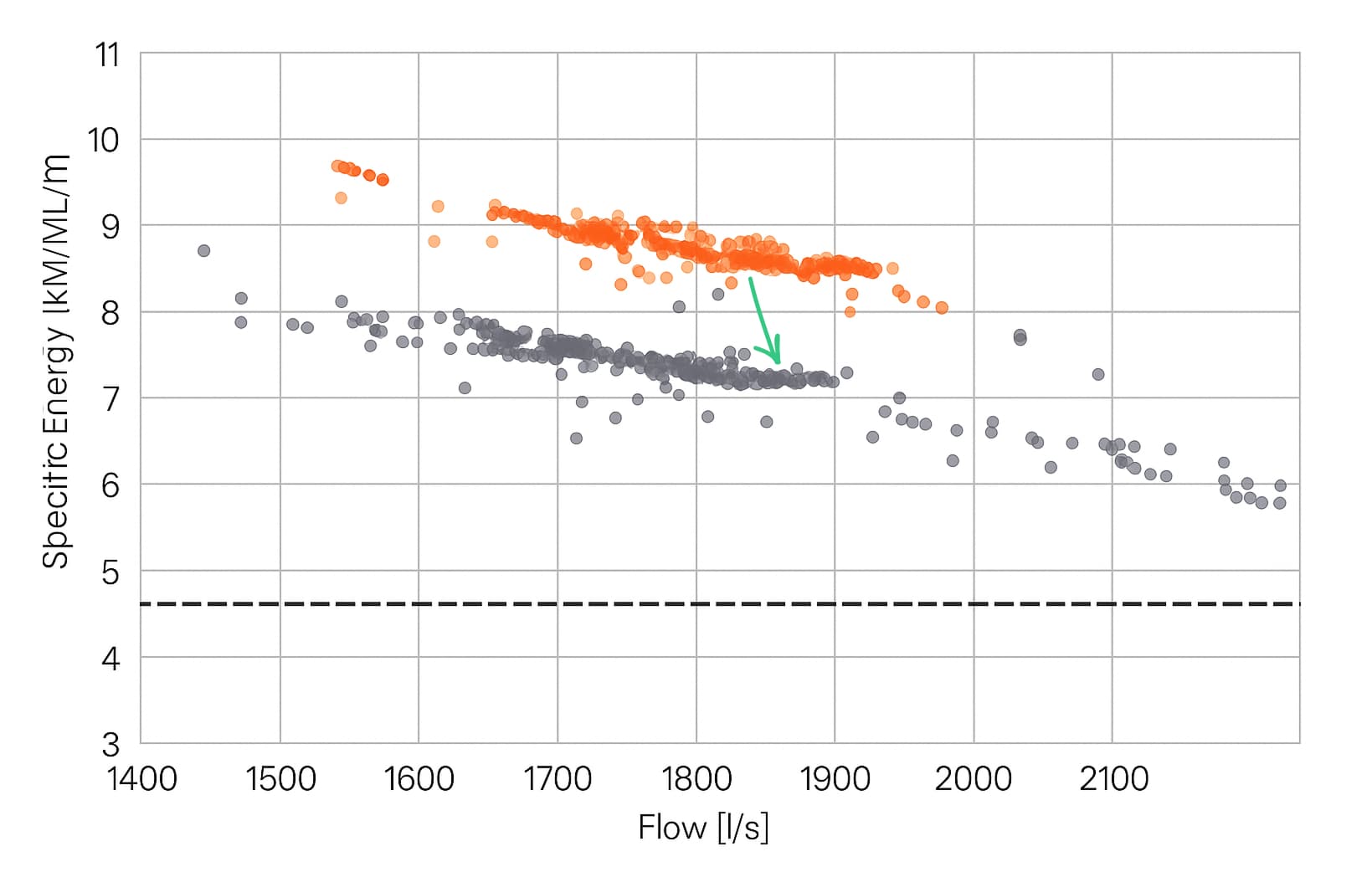

By combining electrical signature measurements from assets, collected and analyzed by SAM4, with existing telemetry data on flow, head, and pump activity, we were able to present Sabesp with a clear and continuous picture of real-time pump performance and energy efficiency.

During a six-month pilot, our SAM4 analysis uncovered major optimization potential:

- 1050 MWh in annual energy savings

- €46,000–€52,000 reduction in annual costs

- 450 metric tons CO₂ emissions identified as avoidable

Specifically, Samotics identified several opportunities to reduce energy use by improving how Sabesp operated its submersible pumps. One example was the discovery that using an updated set of pumps (labeled 1, 2, and 3) together achieved the required flow rates at a much lower specific energy consumption than the previously used combination of pumps 1, 2, and 4. Insights like this enable Sabesp to reduce its overall environmental impact while strengthening the reliability of critical, inaccessible assets.

Building a smarter approach to asset management

With SAM4 providing 24/7 visibility into submersible pump health, Sabesp now has a scalable method to ensure optimized performance across its vast network. The data from SAM4 enables proactive decision-making, helping engineers focus on the assets that deliver the highest efficiency gains and risk reduction.

As Sabesp continues to modernize its operations, smart monitoring from SAM4 is helping them lay the foundation for data-driven energy management. This will help them save costs, improve reliability, and realize their long-term sustainability goals.