Borehole pumps: the pumping heart of the water industry

Pumps are the lifeline of the water and wastewater industry. Borehole pumps are one type of pump that play a critical role in water distribution to residential areas. Their unexpected failure can lead to major water supply disruptions, impacting many households. Because these pumps are typically submerged and located remotely, they are hard to maintain and keep an eye on.

The Challenge

Submerged borehole pumps are notoriously difficult to reach; they can be found up to 200 meters below ground. In conditions like these, traditional proximity-based technologies, like vibration or acoustic analysis, are inadequate: it is simply too difficult to fit sensors on assets that are located so far underground.

There is another challenge that comes with being blindsided by the condition of your pumps that are located far underground in a borehole; namely the cost of lifting them. Historically, maintenance teams would have to li these pumps from their boreholes to assess their condition. The act of lifting a pump from its borehole is particularly time consuming and costly.

The Solution

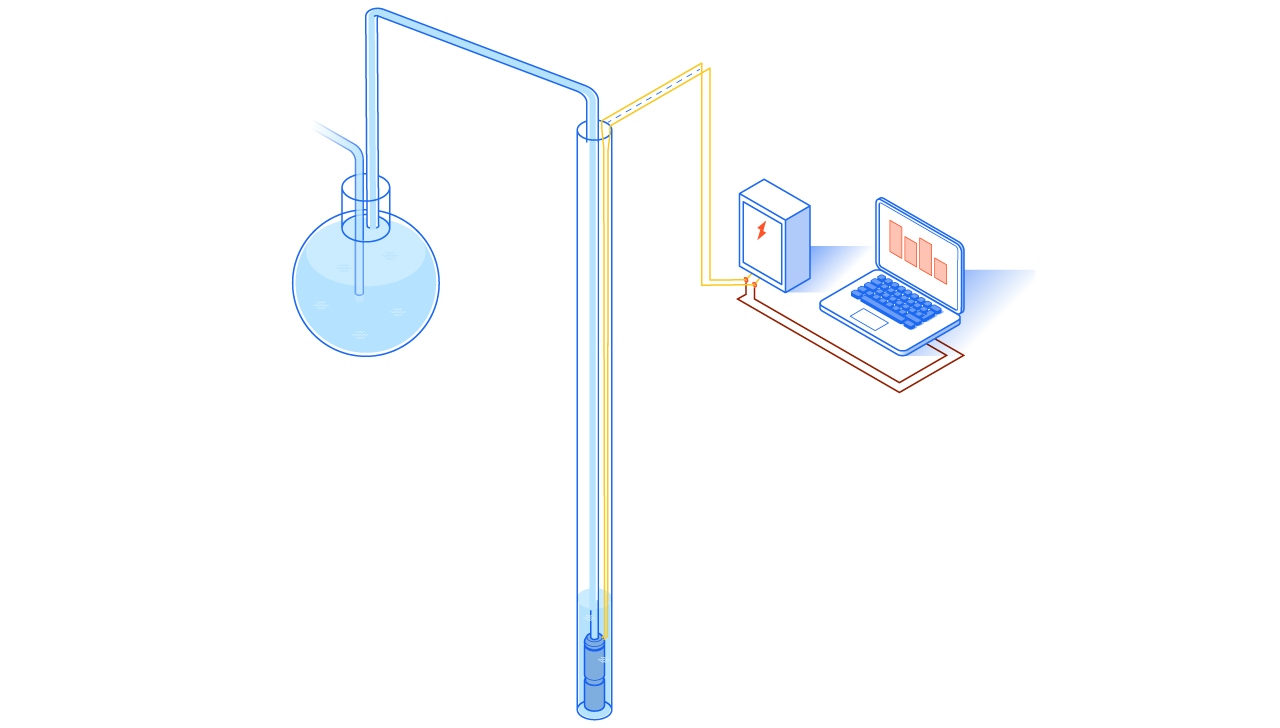

Samotics have developed a system that solves the submerged equipment problem. The SAM4 Health system uses a suite of techniques to analyze a motor’s electrical signature, which means its sensors are installed inside the motor control cabinet (MCC) by design. Because the sensors don’t need to be attached to the machine, it becomes possible to reliably monitor submerged equipment. This means you can monitor all your critical assets in every part of the process, from pumping stations to boreholes to distribution lines to treatment facilities.

In short, there are three key drivers that set SAM4 Health apart from other monitoring systems:

- SAM4 Health is able to go where other solutions do not go. Our sensors are installed in the motor control cabinet, instead of on the asset in the field.

- SAM4 Health can do more than others. We are able to detect electrical and mechanical faults in motors and mechanical faults in the driven asset.

- SAM4 Health makes a true impact on industrial sustainability. By providing concrete insights into energy efficiency and asset health, we are able to provide energy saving opportunities.

In the water industry downtime and associated impacts can come with significant financial and environmental costs. The following section will outline three case studies of how SAM4 Health helped detect faults at an early stage. These detections ensured uptime and avoided potential damage and fines of hundreds of thousands of euros.

1. Early warning of submerged borehole pump clogging

SAM4 Health is widely used to monitor borehole pumps. In one particular case, it has been installed to monitor a set of submerged borehole pumps situated in iron- containing wells.

One early cause of clogging is that of iron build up at the inlet of borehole pumps. SAM4 Health was able to flag the iron deposit nearly a year in advance by detecting patterns of decreasing active power paired with multiple instances of cavitation; these are clear indicators of clogging. The customer was notified as soon as the system saw the fault develop. Subsequently, the customer decided to lift the pump from the well and conduct the necessary maintenance actions. Following the maintenance actions, the data confirmed that the pump’s condition had stabilized.

Given that this pump was difficult to inspect due to its inherent submerged nature, the notification was of great value to the customer. The repercussions of leaving this anomaly undetected would have been overheating of the pump and as a result a significant loss in supply capacity.

2. Early warning of VFD issues on a borehole pump

Borehole pumps are often used to pump up spring water to be processed and turned into drinking water. As a result, these pumps are often located in remote locations which are not easily accessible to maintenance personnel.

SAM4 Health triggered alarms on multiple anomalous occasions:

- an increase in noise on the frequency spectrum.

- atypical behavior in active power for this particular asset.

- and sudden increases in total harmonic distortion.

SAM4 Health detected an unstable supply frequency with an increase in active power and a decrease in power factor. This is an indicator of a pump struggling to keep its speed and load stable and therefore is likely to fail on short notice.

After being notified of the detected anomalies, the customer performed an inspection and found issues related to the variable frequency drive (VFD). The pump was overshooting the maximum current when supplied with 50 Hz.

As a result of these discoveries the maintenance team adjusted the inverter settings of the VFD to prevent the pump from overshooting. A failure to notify the customer of these anomalies could have led to the pump failing which in turn could have led to a hefty loss of supply capacity.

3. Early warning of submerged borehole pump degradation

SAM4 Health is not solely used to monitor borehole pumps in extremely remote locations. In this specific case it detected mechanical unbalance on a submerged borehole pump in a larger production facility.

The anomaly was flagged when a sudden increase of spectral energy at the rotational frequency of one specific pump was detected. This is a clear indication of mechanical unbalance. The customer was immediately notified upon which the decision was made to manually inspect and subsequently maintain the pump. After the maintenance actions had been completed, the data confirmed that the pump’s condition had stabilized.

If the system had not flagged the anomaly, it could have led to serious pump damage and as a result significant supply capacity losses.

The conclusion

Borehole pumps are critical assets across various settings in the water industry. Their inherent nature of being located far underground makes it difficult to apply traditional condition monitoring methods. SAM4 Health provides a solution through which you can detect a multitude of critical failure modes well in advance from the safety of the motor control cabinet. This document has outlined a few examples, but this list is by no means exhaustive.