Archimedes screw pumps are essential for water utilities, running 24/7 to keep operations flowing. Though these pumps can last up to 100 years with proper care, failure often begins with the underwater bottom bearing, which can lead to severe damage to both the screw and its concrete housing.

Text continues after the image below:

Detecting these failures in time is a major challenge for three reasons:

- Bearing failures may not trip internal control logic or telemetry, allowing faults to go undetected.

- With the bottom bearing fully submerged, traditional inspection methods are impractical, making it even harder to catch early warning signs.

- Once a failure occurs, repairs can be complex and costly (up to €300,000), requiring crane hire and specialist expertise, leading to significant downtime and resource investment.

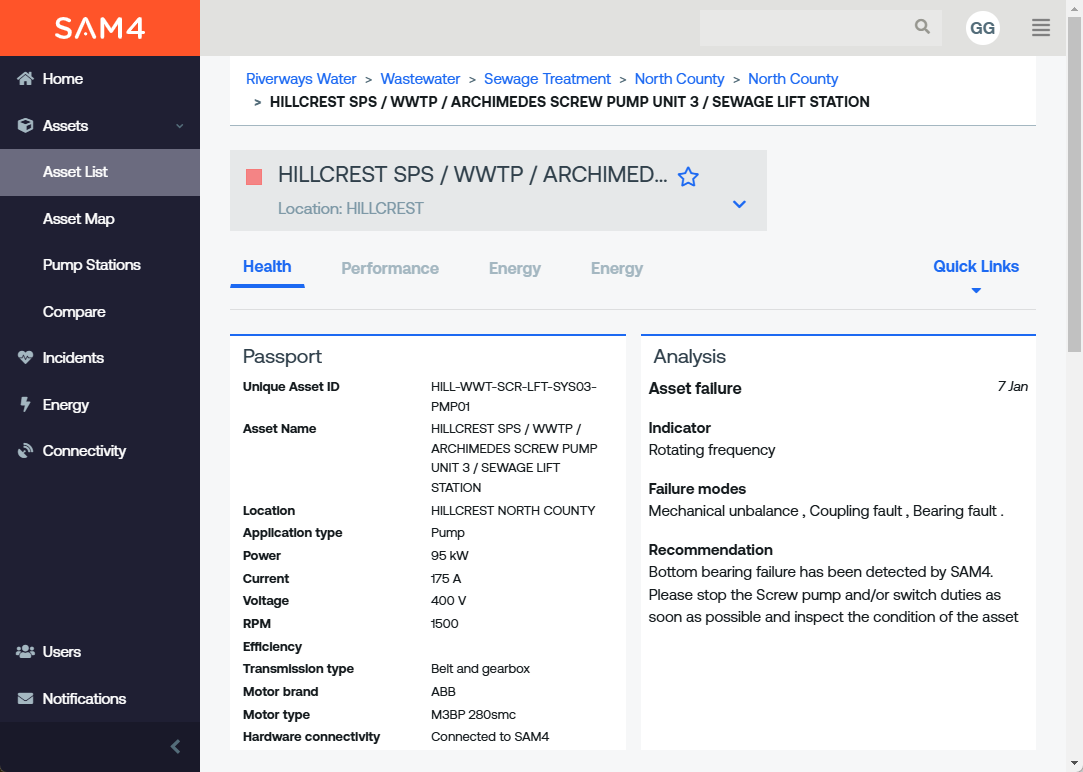

This is why Samotics developed a system to notify customers when a failure occurs, enabling them to stop the Archimedes screw pump and prevent secondary damage. Our asset reliability specialists (ARS) work closely with customers to ensure timely follow-up on predictive alerts. Additionally, Samotics’ customer success team supports customers in refining their maintenance strategy and processes for these pumps.

Detection of bottom bearing failures

When the bottom bearing of an Archimedes screw pump fails, the screw shifts out of position and starts making contact with its surrounding casing. As the motor continues running, this misalignment causes the screw to scrape against the concrete housing, leading to increased friction and mechanical stress. Left unchecked, this can result in severe structural damage, significantly raising repair costs and downtime.

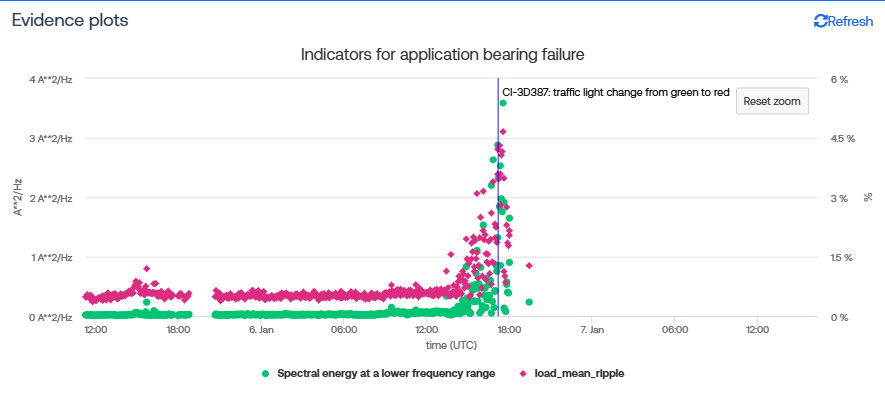

Identifying electrical signal changes from bearing damage

Samotics’ system continuously monitors the pump’s electrical signals to detect changes in load stability and energy at low frequencies. When a bottom bearing failure occurs, the increased resistance from the scraping motion leads to a distinct, sudden rise in these parameters. Our advanced algorithms identify this shift, enabling operators to take immediate action and prevent secondary damage.

Why this matters

Early detection of bottom bearing failures in Archimedes screw pumps helps water utilities avoid costly repairs, reduce downtime, and extend the lifespan of critical infrastructure. This capability directly benefits maintenance teams, asset managers, and operations staff responsible for pump reliability. With support from Samotics’ asset reliability specialists and customer success team, water utilities can improve their maintenance strategies, improve operational efficiency, and ensure uninterrupted service.