The company

Nyrstar is one of Europe’s leading zinc smelters, refining over 300,000 tons of high-purity zinc every year. Operating continuously, the plant relies on pumps, conveyors, agitators, and other critical assets to keep furnaces running. As a vital part of the global zinc supply chain, the company cannot afford unplanned downtime.

The challenge

Despite a well-established maintenance strategy, Nyrstar faced recurring challenges with unplanned equipment failures. Conveyor stalls and pump seizures caused furnaces to cool, logistics delays, and production losses costing hundreds of thousands of euros per hour.

Maintenance teams were also frequently called out in the middle of the night to respond to urgent breakdowns. The site needed a way to identify risks in advance, reduce reliance on firefighting, and protect critical motors while adapting to evolving workforce needs.

The solution

Nyrstar deployed SAM4, Samotics’ smart asset monitoring solution, across critical assets. SAM4 listens to the electrical heartbeat of every motor from inside the motor control cabinet, requiring no sensors mounted on the machines themselves. The system delivers continuous real-time insights, enabling early detection of developing faults and eliminating guesswork.

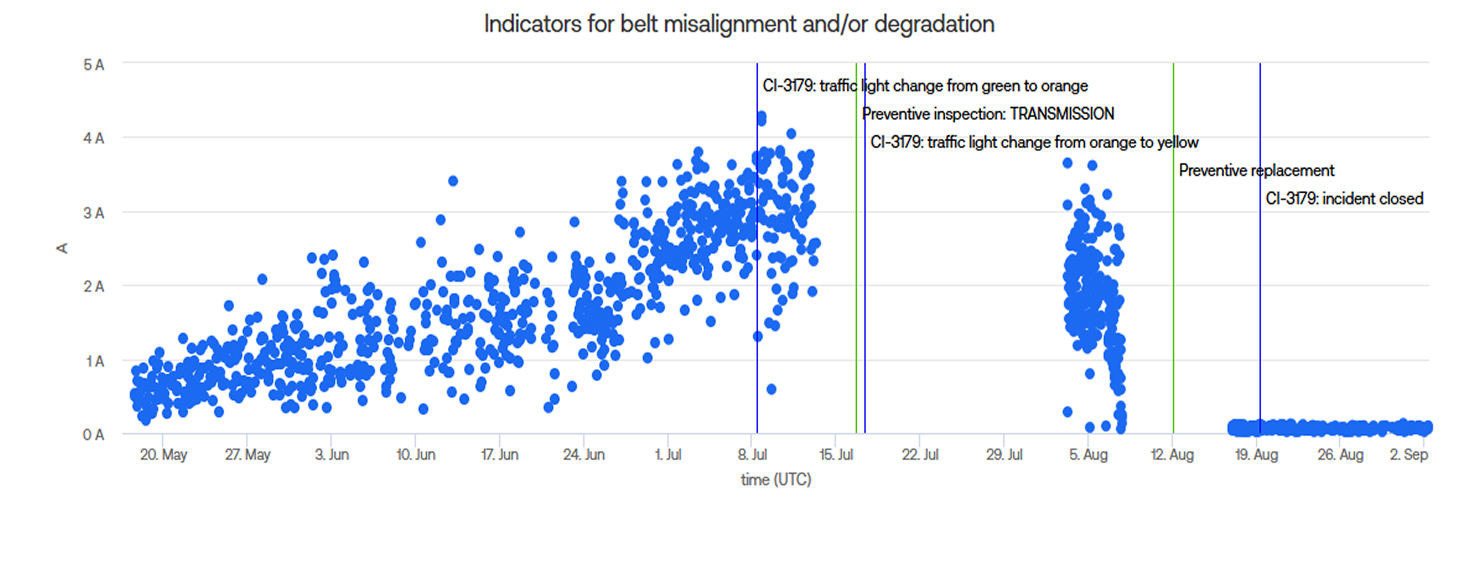

Effective detection of belt misalignment

Within just 1.5 months, SAM4 detected misalignment in the belt and pulley transmission for this pump, allowing replacement during a scheduled stop rather than a production-halting breakdown. Inspection revealed the belt had slipped off its pulley and both pulleys were worn. By addressing the issue during a maintenance window, the site avoided an unplanned line stop and potential production loss.

The result

SAM4 has become an essential tool in Nyrstar’s strategy to protect uptime, safety and operational efficiency. In the first eleven months, maintenance shifted from urgent nighttime repairs to scheduled, controlled interventions.

Being able to catch such issues early has helped the site shift from reactive firefighting and urgent nighttime repairs to planned, efficient maintenance that secures uptime and safeguards production.